Tolerance:D +/-.0003, L +/-.002.Products can be finished ground to meet customer’s OD and length specifications.

Our 3/4 inch, and 7/8 inch dome inserts have found successful application in geographical locations ranging from West and East Texas, New Mexico, Oklahoma, Arkansas, WV and NEUS regions.

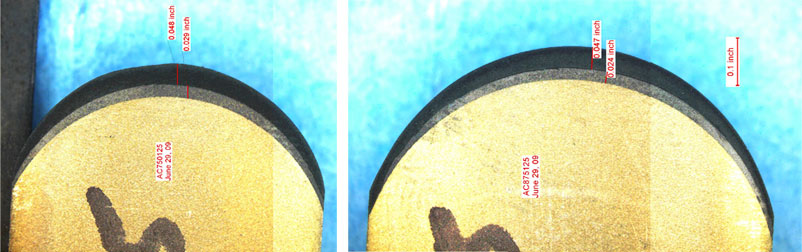

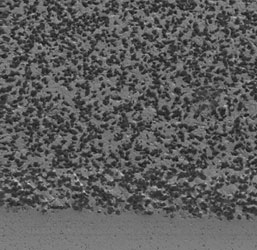

Inserts are evaluated for their metallurgical features by microscopic examination of the section.Following micrographs show 1) the working layer integrity 2) the bonding between the working layer and the transition layer and 3) the interface integrity between transition layer and the carbide substrate.As can be seen in the following micrographs, the layers are homogenous and well bonded. |